I really liked the look of the finished product, at least according to the pictures on the set of plans, and really wanted to try some real dovetails, so I bought the plans and hied myself down to the wood store to pick up some cherry. (Wow, was it expensive. Seriously.) My instructor in the course was all gung ho about me giving this a try, and helped me as best he could (while still tending to the rest of the class).

Over the 27 hours of the course, I managed (barely) to make the carcass of the thing. I spent four straight classes doing nothing but cutting the dovetails. It was bloody hard work, and I think next time I might just use a router. (Kidding! As long as I'm working with softer wood.)

Anyway, at the end of the class, I brought my work-in-progress home to finish it up... and it sat in the corner of my office for the next 18 months. I managed to drag it down to the work shop long enough to give it some cursory sanding, and again another time to mortise in the hinges for the lid, but I was finding the process of actually finishing it somewhat daunting.

Well, my goal for my work-funded life improvement initiative this year was to start actually finishing some things (in more ways than one), so I resolved to get this thing done as my December project. (I'm a little late because the garage/workshop is not only not heated, but also poorly insulated, which makes applying finishes in sub-zero weather something of an ill-advised challenge, if not just plain impossible.)

So this is what the toolbox (or at least the pieces of it) looked like when I dragged it out into the light:

Actually, I think that was after I'd already done a fair amount of sanding and prep (and some chiselling to make the lid fit properly). I had already decided to try shellac on this project, and got some very helpful advice from my father-in-law with regards to not going overboard with the whole "Let's try French polishing on my first shellac project like an idiot!"

So I mixed up some two-pound cut using some very nice shellac flakes I picked up at - surprise! - Lee Valley:

It took a few hours for the flakes to break down:

Once it did, I used a combination of a really poor-quality bristle brush (bit of a mistake there) and a foam brush (another bit of a mistake there) to put on two coats of shellac. I thinned the second one slight as it was really cold in the garage and I was finding the shellac hard to manipulate once it hit the surface of the wood. Next time, I think I will thin the first coat even more, and use a rag (also known as a rubber or a fad) to apply the shellac. Here's what it looked like:

Because I had put the shellac on a little thick, I had to do a LOT of sanding and even more work with the steel wool, but I managed to get a really nice sheen to the surface afterward.

Unfortunately, that's when the REALLY cold weather hit and I had to wait more than a week to put on a couple coats of wipe on poly. I actually had to spend the better part of the day yesterday using every portable heater I had to get the garage up to minimum temperature. It was worth it, though. the poly really puts a shine on it:

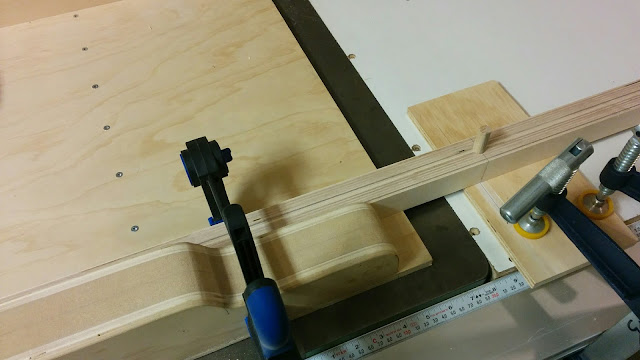

Then, today, it was just a matter of putting on all the hardware (I got to make TWO jigs!) and - after some discussion - finding a home for the damn thing:

I cannot possible tell you how good it feels to not only cross that one off the list, but to have it turn out so well.

Okay, so the finish isn't perfect, but I learned SO much during this process that I'm pretty confident I'll be able to get pretty close the next time I use shellac.

Bonus project!

So, I wanted to actually post about this before New Year's, but couldn't for rather obvious reasons. Fortunately, the last person slated to receive one has finally taken possession, so...For Christmas presents this year, we decided to make bomber holders for a few select friends. The growler carriers I made were a pretty big hit with some people, and so we thought a similar idea, but designed for bombers, would make a nice present for the beer afficionadoes in our lives. The War Department also thought it would be nice to include a bottle opener on the case (as we have yet to encounter a twist-off bomber), and we found some beautiful ones at, well, Lee Valley (of course). She also helped pick the beers that went into them - what, you thought we'd turn them over EMPTY? We're not savages!

Anyway, these were a lot of fun to make, aside from all the goddamn math, and despite a tiny bit of an issue when I tested the strength of the plywood veneer with an excess of carpet tape:

I had to remake those pieces, obviously, but the holders turned out really nice, and everyone that got one seemed to like theirs.

I made them out of recycled furniture, by the way, AND I got to use my spline jig! Oh, happy day!